Expert Design Guidance and Installation Support

From your purchase to a successful setup, we’ll be with you every step of the way. Our knowledgeable engineers will assist with the design and installation of the best biofouling system for you.

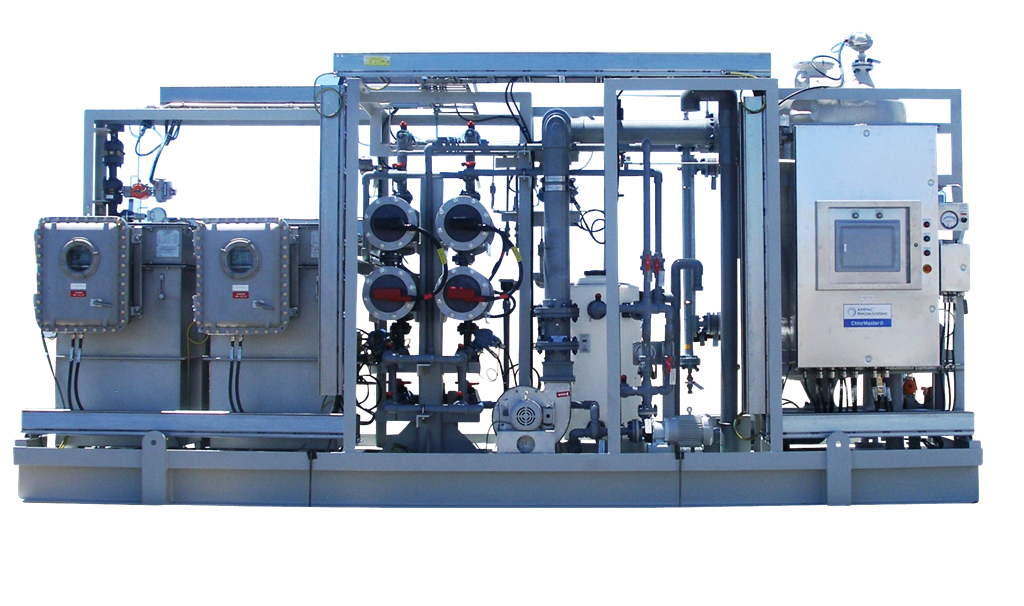

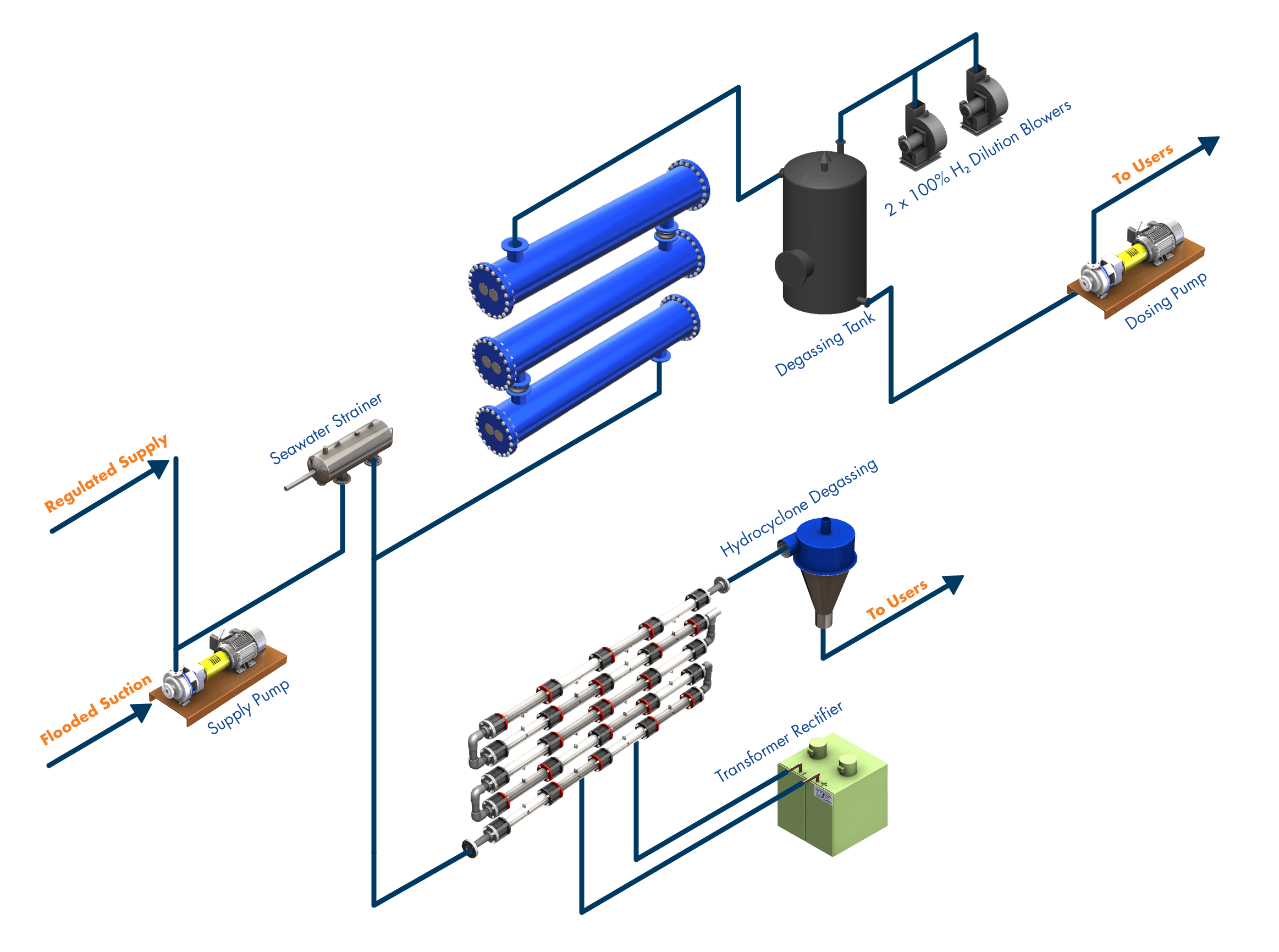

Our electrochlorination systems protect against macro- and microfouling by creating a continuous stream of meticulously concentrated chlorine.

Increase uptime and prevent fouling of your pumps, pipes, and heat exchangers through the process of electrochlorination. With our PEPCON® electrochlorination and biofouling control systems, you’ll find continuous monitoring for micro and macro fouling, easy maintenance, and trusted results. Plus, you’ll save space, logistics, and money over routine chemical injections

From your purchase to a successful setup, we’ll be with you every step of the way. Our knowledgeable engineers will assist with the design and installation of the best biofouling system for you.

We’re proud to provide dedicated, comprehensive, and ongoing support for you so you can maintain your new system with ease, including convenient shipments of the right parts and chemicals for system care, 24/7 access to experts, and more.

Support doesn’t end when your system is installed. From annual inspections to periodic electrolyzer cell replacements, we provide ongoing service so you can get the most out of your new system.