Shipyard-Ready Systems That Slot In And Sail Through Reviews

Pre-engineered utility packages delivered with the submittals shipyards expect—including class and flag certifications.

Who This is For

Naval Architects | Shipyard Engineering & Procurement | and Owner Tech Reps Coordinating Utilities During Design and Build

New-Build Priorities

Predictable Footprints | Clean Tie-ins | Document Packages That Confirm Compliance Expectations

.png?width=1200&height=1200&name=H2O%20WEBSITE%20SQUARES%20(3).png)

CHOOSE YOUR PATH

BROWNFIELD REPLACEMENT(MODULAR SYSTEMS)

Fast, fit-for-access retrofits that tie into legacy utilities and restore uptime quickly.

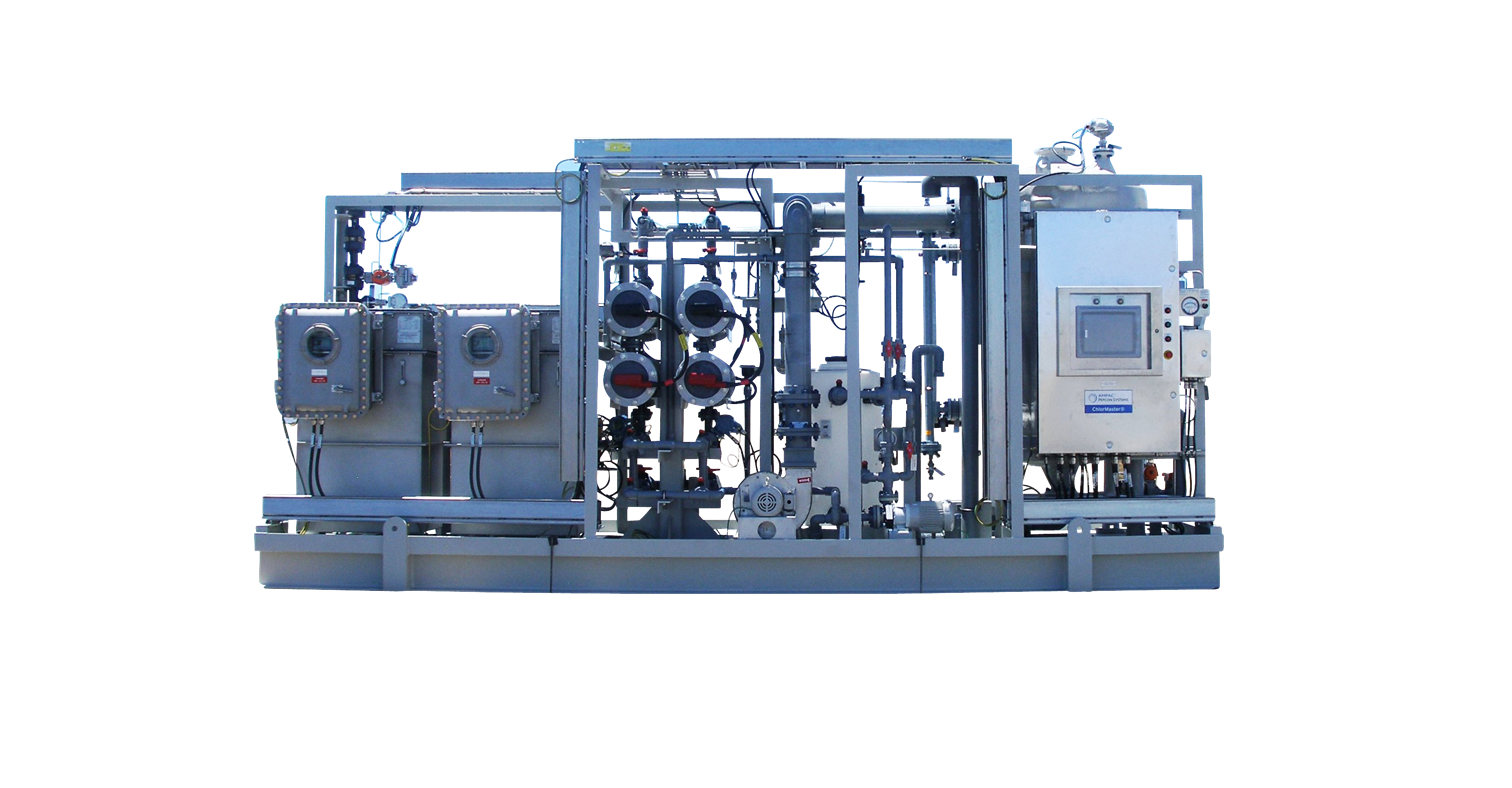

GREENFIELD NEW BUILDS(SKIDDED & ENGINEERED)

Single-skid packages built to spec for shipyard lift-and-set installation and clean EPC review.

Applicable Product Families

BLUECUBE RO (SKIDDED)

LEARN MORE

PEPCON EC MGPS (SKIDDED)

LEARN MORE

BOSS BILGE (SKIDDED)

LEARN MORE.png?width=825&height=718&name=C_Painted_Front_Left__26216.1532008898.1280.1280__96650%20(2).png)

CRAPZAPPER MSDS FOR THE PROGRAM SPEC

LEARN MOREWhat We Deliver

- Skidded marine packages sized and arranged for integration at the yard.

- Class/flag-aligned documentation (informational) to satisfy builder/owner expectations pre-install.

4-Step Yard Work Flow

Why Choose H2O?

Designed with shipyards in mind: our skidded systems integrate cleanly, arrive with class and flag certifications, and come documented the way builders and owners expect—keeping design reviews simple and installations predictable.

FREQUENTLY ASKED QUESTION

How fast can a replacement system be installed and brought online?

Our brownfield modules are designed around your existing tie-ins and access routes, so installation is measured in hours or days—not weeks. Systems are fully function-tested before shipment to minimize offshore hookup time and speed commissioning.

Can your systems fit through our hatches and stairwells?

Yes. All modules are dimensioned for offshore access limits. We break down systems into subassemblies sized to pass through hatches, ladders, and stairwells, then reassemble offshore for a clean tie-in.

Will the new system match our existing piping and electrical tie-points?

Replacements are engineered to your legacy connection dimensions. Tie-in points are confirmed during the assessment phase so you don’t face field modifications or unplanned hot work offshore.