When you’re planning maintenance for your offshore oil rig or another large vessel like an FPSO, the plans you’re likely most interested in are those that pertain directly to oil production (or your end goals). After all, those machines are the reason you’re in the water. It’s easy to see how the time you spend maintaining those machines is well worth every second.

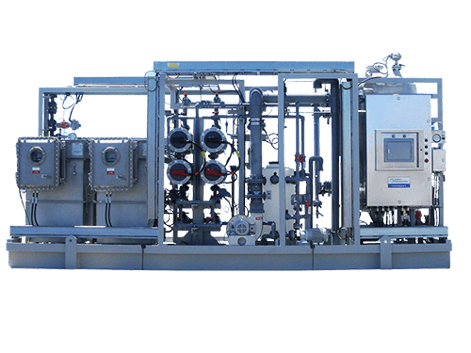

However, there is a whole host of machines aboard your vessel that are equally important, if not more so. These are the systems that help support the safety and health of your crew while you’re out at sea. A prime example is your vessel’s hypochlorite generator—a machine that functions as a vital part of your at-sea water treatment system.

Some of the most crucial parts of your hypochlorite generator are pieces called electrochlorination cells. As part of your routine maintenance, it’s a good idea to check these. They require care and even replacement over time to ensure that your hypochlorite generator is working the way it should.

How can you tell exactly when to replace your electrochlorination cells? How can you take care of them in the meantime to make sure your systems last as long as they can? We’ll talk about the exact ways to tell when your electrochlorination cells need a little care in this piece.

What are electrochlorination cells? Why are they important for your day-to-day safety and performance?

As one of the critical equipment aboard your vessel, your hypochlorite generator treats incoming water with generated amounts of bleach. It does so with specialized electrochlorination cells, or electrolyzers, that use electricity as well as naturally occuring chloride ions in seawater to help disinfect your water lines.

Simply put, electrochlorination cells are the small chambers in which electricity helps turn the salt in seawater into sodium hypochlorite (or bleach) through a chemical reaction. Once you have that sodium hypochlorite, you’ll be able to kill unwanted marine growth in incoming seawater. This can help you run the firewater and cooling water lines you need for operations around your vessel or facility.

Chemical versions of water treatment and disinfection systems depend on electrochlorination cells to get their work done. These types of units can kill almost anything that’s harmful in incoming seawater. After purifying the water so you can use it safely, the system will take care of dumping the refuse overboard.

Because a sodium hypochlorite generator plays a key role in producing safe water for your vessel, and the electrochlorination cells help make that system work, electrochlorination cells help ensure you have safe, clean water on board your vessel. If your electrochlorination cells aren’t working, then you and your crew might suddenly find yourselves in an unsafe scenario.

What happens if you don’t maintain your sodium hypochlorite generator’s electrochlorination cells?

Maintaining all of the systems on your vessel takes time, and it can seem like your system’s electrochlorination cells don’t need much attention. However, taking a few minutes to routinely walk by and take a look at your generator can save you a lot of trouble (and money) in the long run.

Your vessel’s electrochlorination cells are directly responsible for making seawater clean and usable. If you don’t maintain or replace them responsibly, you might not have safe, clean water to use on board your vessel.

If you don’t have usable water to fuel your vessel’s cooling water or firewater lines, you may find that multiday excursions are difficult or impossible. You might have to pay for costly offshore repairs or deliveries of clean water, which will take time. You, your crew, and your guests also run the risk of either dehydration or illness after exposure to unsafe or unclean water.

There’s also the question of the harm you might inadvertently be doing to your hypochlorite generator if you let your electrochlorination cells go too long without attention. Your hypochlorite generator can cost upwards of $500,000 to replace, which alone makes it an investment worth protecting.

Save yourself some worries about money and safety by regularly taking a few minutes to check the status of your electrochlorination cells. You’ll definitely thank yourself in the long run.

How can you tell when your electrochlorination system or cells need maintenance or attention?

There are five simple ways you can check to see if your electrochlorination cells need to be cleaned, maintained, or replaced. Check for these during your regular inspections:

1. Check to see if the voltage across the electrodes in your electrochlorination cells is dropping.

The voltage on one specific electrode should not vary from the others by more than about 10%-20%. If you find that the voltage is off, check the cable connection, and also see if there’s any end-pin damage.

If installed incorrectly, the electrode may dissolve, which would render the entire cell faulty or useless. Fortunately, if this seems to be your main problem, there’s a simple solution. Perform an acid-cleaning procedure on your cells with a 6%-7% solution of hydrochloric acid. As long as you acid-clean correctly, this should fix the voltage issue.

2. Physically inspect the cell by opening the electrolyzer if the voltage issue remains constant.

If acid-cleaning the part doesn’t seem to help, open up the cell. Inspect for any short-circuit issues, improper coating, hard hydroxide presence in the electrode, and deformations. If you find any issues along these lines, take pictures of them. If you send those pictures to the manufacturer, it will be able to help you figure out exactly what to do.

If your electrodes need to be replaced, H2O LLC can send experts on-site to replace them. H2O LLC’s team can also address any hard hydroxides you find to ensure that your hypochlorite generator will be up and running before you know it.

3. Check on the integrity of all electronic parts, such as the ones in control cabinets.

Sometimes, troubleshooting these parts of your generator is all you need to do. When you open the control cabinet of your hypochlorite generator, you should be able to identify any alarms that you might need to reset.

Check to see whether all of the supply levels and modules are healthy. Using the manufacturer’s guide, make sure that the processor seems to be working as it should. All fuses should appear healthy and normal as well. If you identify any other issues with the electronic parts of your generator, take a picture of the issue and call H2O LLC for further information.

4. Perform a visual inspection of the electrochlorination cells themselves.

If they are not maintained properly or are in need of replacement, the cells will start to show signs of wear. The plates, visible externally, will begin to dissolve. The hard coating will begin to wear off. When your voltage starts going too high, it’ll eat away at the metal forming these parts. If you can see this happening, that’s a good indication that your electrochlorination cells are in need of care or replacement.

5. Check to see if the water is being properly cleaned.

Remember, the primary job of the hypochlorite generator is to help sanitize water. If the water isn’t getting cleaner, then your system isn’t working as it should.

Fortunately, it’s relatively simple to check this. If you can’t see through the water coming out of your water treatment system, it isn’t being properly cleaned. There should also be some residual chlorine in the water after its treatment. Check to see whether there is a 0.2-0.5 ppm concentration of chlorine in the treated water. If not, you may need to begin the troubleshooting process.

How often should you maintain your hypochlorite generator or the electrochlorination cells inside?

The simple answer is “as needed,” based on your frequent visual inspections. However, a good rule of thumb is that you should perform full maintenance at least once a month to ensure that your hypochlorite generator is working the way that it should.

If you take the time to ensure that your electrochlorination cells are working well, your sodium hypochlorite generator and water sanitation and treatment systems will work better—and last longer. This can save you a lot of money, and it can help ensure that you have everything you need to be safe and productive while you’re at sea.

Alternatively, skipping a month or two of maintenance checks could have frustrating repercussions. Make a quick check on the health of your electrochlorination cells a part of your weekly sodium hypochlorite generator walk-by. The earlier you notice that anything may be awry, the earlier you can work toward a solution.

If you have any questions about electrochlorination cells, or if you need a second eye on an issue to help you diagnose a problem, H2O LLC is always ready to assist. Depend on H2O LLC as a great resource for any questions (including pricing queries) about electrochlorination systems.