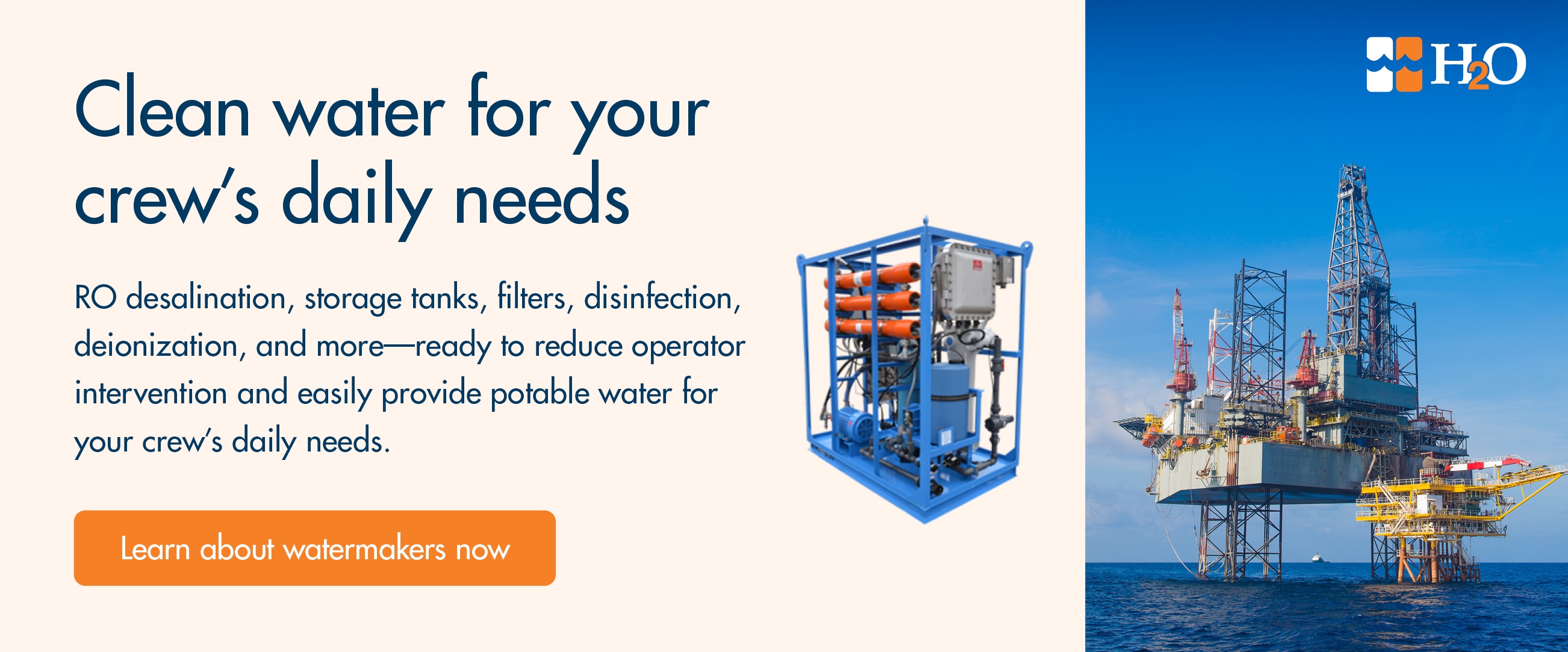

When it comes to the critical choice of selecting a watermaker for your offshore, marine or industrial location you have very important factors to consider.

1. WHEN YOUR EQUIPMENT BREAKS OR NEEDS MAINTENANCE, WHO WILL BE THERE FOR YOU?

Since an offshore watermaker is a type of mechanical equipment that pumps corrosive seawater at high pressures, it will eventually require maintenance. When your crews don’t have the time or expertise to troubleshot problems, it is beneficial to have a watermaker vendor that can send qualified field support personnel to assist. Many manufacturers have outsourced the field service part of their business to reps or agents who have very limited training or knowledge on their systems and can only serve as an expensive middleman between you and the watermaker factory.

When you call in for help for your water treatment systems, will you talk to an expert who’s built and serviced watermakers for years or an order-taker who looks for the serial number on your unit and the part number you want to buy? The right customer service representative can save huge amounts of time and money by identifying the root cause of the problems, and not just the symptoms.

2. NOT ALL WATERMAKERS WILL MAKE SAFE, POTABLE WATER.

Your water supply has the potential to affect the health and safety of every member of your crew. It’s a common belief that all watermakers make potable water that is safe for your crew and distribution systems. This is simply not the case. Many manufacturers state, in writing, that the water their units produce is for utility use only and should be segregated from potable water piping systems. Water produced from the reverse osmosis (RO) process requires additional treatment to ensure it remains free of bacteria and will not corrode your piping systems.

In addition to these potable water-related safety issues, there is also the fact that the reverse osmosis (RO) process operates at high pressures. Things like relief valves and high-quality pressure vessels are necessary to ensure the safety of your crew.

3. A WATERMAKER IS ONLY AS GOOD AS ITS WEAKEST LINK.

The only two things a watermaker really needs are a pump and membranes. These items also account for a large percentage of the system’s cost. You can cut corners by selecting a pump that’s too small (high recovery) or by using too few membranes (high flux). When such decisions are made, the cost savings realized on the purchase price are quickly erased by high operating costs.

Seawater, as we all know, is highly corrosive and the materials that offer good service life are not cheap. Use of brass, bronze, and even 300-grade stainless steels are going to offer a limited life in seawater reverse-osmosis service due to pitting corrosion. Manufacturers should use thermoplastics and fiberglass (when acceptable) to lower system costs. If the conditions or client call for metallic piping or vessels, select materials with a pitting resistance equivalent number (PREN) greater than 42 where possible.

4. YOU NEED TO GET RID OF THE GUNK FIRST.

To remove the salt we first have to take out the dirt, seaweed, sand, mud and algae. Based on location, wind, tides and water depth, the amount of particulate matter in the water and even the salinity can vary. One thing is common, however: membranes, while they are great at separating salt and other ions from water, are a very expensive way to remove suspended particles (dirt). For this reason, industry-standard practice is to filter solid particles in the water down to 5-10 microns. To put that in perspective, the human eye can only see down to about 50 microns. The number of stages and even the sizes of filters should be properly selected to offer adequate time between filter changes and ensure a reasonable membrane life. Your reverse osmosis (RO) vendor should be able to recommend a pre-filtration system so you don’t end up with one that requires expensive and time-consuming daily maintenance.

5. LOOK FOR A MANUFACTURER THAT STICKS TO THE K.I.S.S. PRINCIPLE IN IT’S PRODUCTS.

How much automation is too much? Murphy’s Law states that when things can go wrong, they will go wrong. In the age of the smartphone, many watermaker manufacturers have started offering a laundry list of automated features and fancy touch-screen interfaces that control and monitor every aspect of the equipment. The problem is that all of this added control requires more valves, positioners, stepper motors, transmitters and electronic components, which adds numerous points of potential failure. Look for a manufacturer that sticks to the K.I.S.S. (keep it simple and straightforward) principle in their watermaker design and uses a minimum number of only the highest-quality components.

6. IN WATERMAKERS SMALLER IS NOT ALWAYS BETTER.

As we have discussed, watermakers will eventually require maintenance. Beware of systems that are so compact they are not serviceable. A simple two-minute job like tightening a leaky fitting can turn into a full-day ordeal when you have to remove the pump, motor and two other pipe spools to get a wrench onto the leaky fitting. While we’re on the topic of size, another place where smaller is not better is pre-filters. The life of a pre-filter is directly related to its surface area. The bigger the filter, the greater its surface area. When the surface area is larger, the filter can hold more dirt and be used longer before you need to change it. Go big, or change it daily.

For a free seawater analysis or a no-cost review of your poorly performing watermaker, call or send us a request via our website.