PROJECT FACTS

The Juniper project is in the East Mayaro Block (EM) off the south east coast of Trinidad and Tobago.

CHALLENGE

The platform employs a crew size of 10 men for 12 hours per day, approximately two times per week. The treated sewage needed to meet both IMO and local Trinidad and Tobago discharge standards. BP specifications required a high level of redundancy and a very high level of internal company standards to be met from instrumentation to paint.

SOLUTION

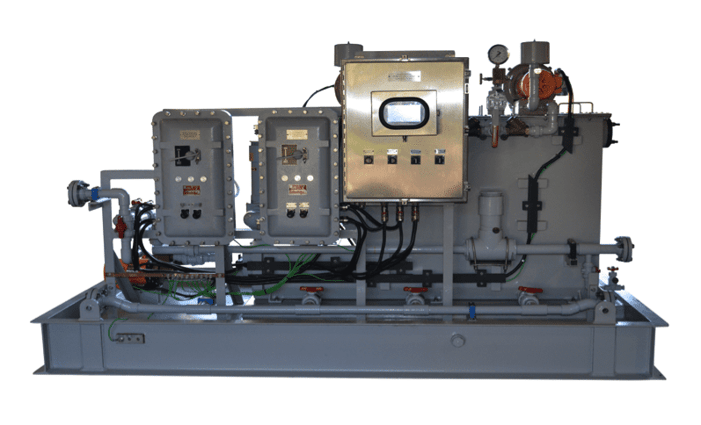

H2O provided a highly customized CZM-182 Crapzapper® marine sanitation device. The treatment process met the required discharge limits for BOD, COD, TSS and nutrient removal. A base frame was included to house the sewage treatment plant and the associated controls and equipment. The specifications required redundant local MCC, blowers and discharge pumps to be fitted onto the skid. The local control panel has an HMI and an PLC with Modbus communication. Transmitters were used throughout the package in order for the client to remotely monitor and control the system via the DCS. A very significant documentation program was called for, including blast loading calculations, baseline datum thickness testing, lifting and loading calculations, X-ray weld analysis and PMI testing to name but a few. A substantial documentation package in excess of 80 individual documents was also provided for the package.

RESULT

H20 was able to provide a sewage treatment system that met the environmental discharge quality limits even with the sporadic loading conditions. Our engineering group was able to deliver on the stringent project specifications, quality standards and documentation requirements for the project. BP has a sewage treatment solution that is reliable and provides many decades of worry free service.