RETROFIT OR NEW BUILD—NEED MARINE WATER & WASTE PACKAGES THAT JUST FIT AND PASS?

From in-service vessel replacements to shipyard integrations, we deliver class/flag-ready freshwater, disinfection, bilge, and marine growth prevention systems sized for your fleet.

WHO WE SERVE

Naval Architects, Shipyard Engineering and Procurement, Owner technical reps, and port/marine engineers managing documentation and install windows across mixed fleets.

WHAT’S AT STAKE

(AND HOW WE HELP YOU SOLVE IT)

Existing installations

(retrofits and replacements):

A failed system can jeopardize sailing schedules, disrupt crew operations, or extend costly drydock stays. Space and access are tight, and connection points often vary between vessels. We design compact, modular replacements that fit through hatches, tie in cleanly to existing piping and electrical systems, and start up quickly minimizing yard time and getting your vessel back in service fast.

New builds

(shipyard projects):

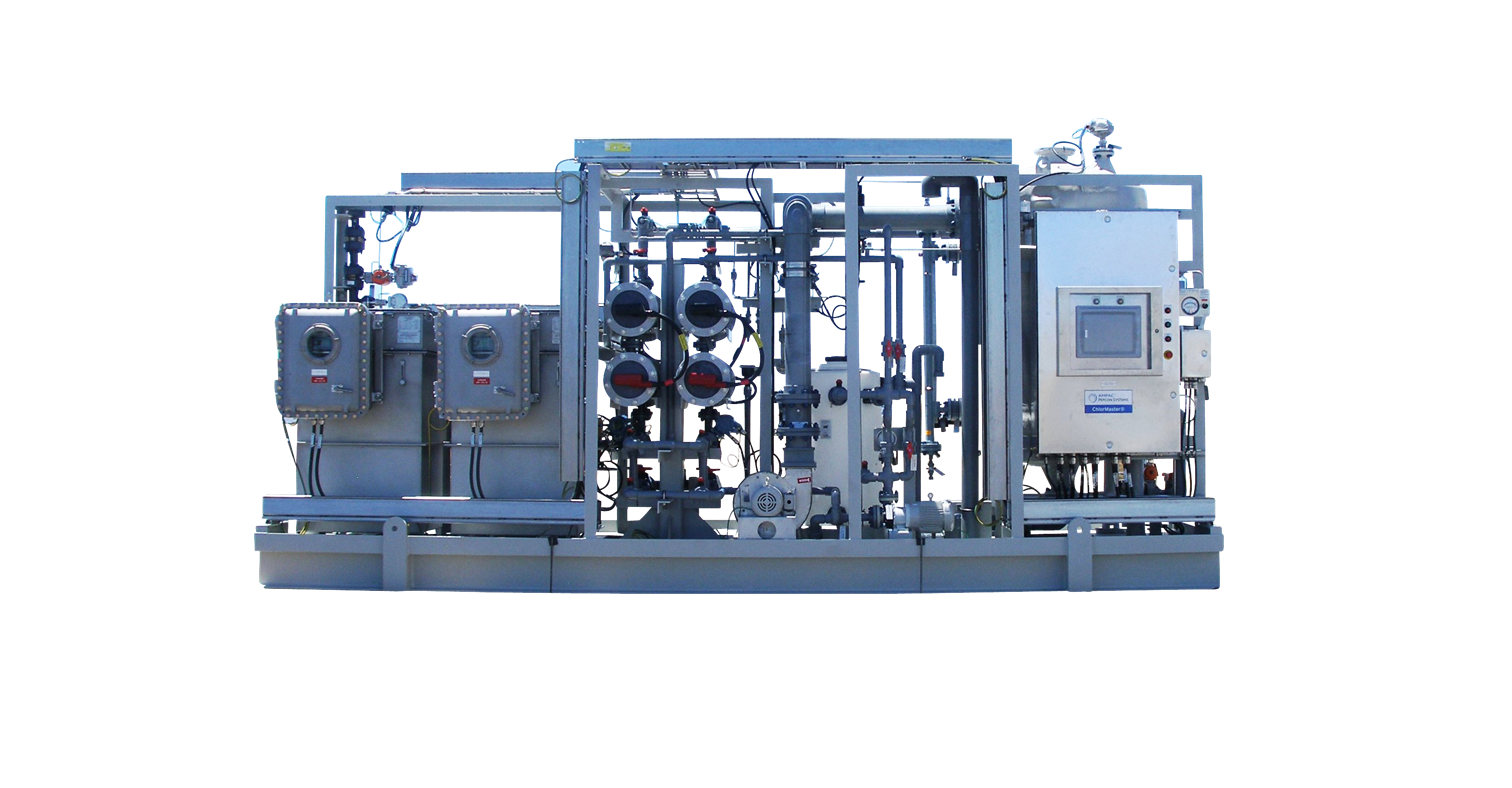

Shipyard teams need packaged systems that drop in cleanly, meet class and flag requirements, and keep production moving. Our skidded packages are engineered to spec, built from marine-grade materials, and shipped with all documentation needed for seamless installation and startup.

.png?width=1200&height=1200&name=Untitled%20design%20(16).png)

CHOOSE YOUR PATH

Replacement & Retrofit

Drop-in, right-sized packages that simplify change-outs during drydock or sport calls.

New Build Vessel Programs

Pre-engineered, class/flag certified-systems sized for the spec and delivered for clean integration.

CORE PRODUCT FAMILIES FOR OFFSHORE

BLUECUBE RO WATERMAKERS

Freshwater production systems engineered for tight-space retrofits or turnkey shipyard installation.

RENTAL QUOTE

PEPCON EC MGPS

Electrochlorination systems that prevent marine growth and keep seawater circuits clear.

RENTAL QUOTE

BOSS BILGE WATER TREATMENT SYSTEMS

Compact, IMO-compliant bilge separators built for reliable operation on any vessel size.

RENTAL QUOTE.png?width=825&height=718&name=C_Painted_Front_Left__26216.1532008898.1280.1280__96650%20(2).png)

CRAPZAPPER MARINE SANITATION DEVICES (MSDS)

Rugged, class-approved sewage treatment systems built for dependable service.

RENTAL QUOTEWHY H2O OFFSHORE?

Class/flag-ready documentation, right-sized footprints, and fast installations that respect yard and service windows—so vessels get back to work on time.

FREQUENTLY ASKED QUESTION

Are your systems class-approved and built to meet flag-state requirements?

All systems are designed and certified to meet applicable class society and flag regulations, and we supply the supporting documentation and test records needed for vessel certification.

Can your systems be easily integrated into new vessel designs?

Our systems are delivered as self-contained skids with defined footprints, loads, and utility requirements. This allows Naval Architects and shipyard engineering teams to plan piping, electrical, and structural interfaces early in the design process.

How much space and access do your systems require during installation?

We design packages around the access constraints common on vessels. For new builds, they’re skidded for single-lift installation. For refits, they can be modularized or hatchable to fit through existing access routes.

What level of documentation is provided for shipyard installation and commissioning?

We provide complete installation, operation, and maintenance documentation along with electrical and piping interface drawings. This ensures shipyard teams can install and start up the system without delays or ambiguity.

How do you ensure materials are suitable for the marine environment?

All materials and coatings are selected for marine duty, with proven corrosion resistance and durability. This includes stainless or coated structural steel, marine-rated electrical enclosures, and offshore-grade components.

How long does installation and commissioning typically take?

Our systems are designed to minimize yard time. Pre-fabricated skids reduce onboard assembly, and pre-shipment testing speeds up commissioning. Most systems can be installed and started up within standard drydock windows or short port stays.

How long does installation and commissioning typically take?

Our systems are designed to minimize yard time. Pre-fabricated skids reduce onboard assembly, and pre-shipment testing speeds up commissioning. Most systems can be installed and started up within standard drydock windows or short port stays.

Can you customize systems to fit specific vessel layouts or owner standards?

While our designs are standardized for efficiency, they can be adapted for vessel-specific layouts, utility connections, materials preferences, and owner specifications.

-1.png?width=100&name=document%20(1)-1.png)

.png?width=100&name=valve%20(1).png)

.png?width=100&name=handshake%20(4).png)