When space is tight and uptime matters, we make replacements simple.

Engineered replacements that restore all water treatment fast—right-sized for tight spaces, HazLoc-ready, and built for harsh environments

Who is this for?

OIMs, Maintenance Supervisors, Facilities Engineers, Operators/Technicians, and Maintenance Coordinators responsible for restoring uptime fast.

The brownfield reality.

Aging systems, emergency failures, hatch-and-stairwell access, and legacy tie-ins, all inside hazardous areas where documentation and durability matter. Your mandate: restore fresh water, biofouling control and waste water treatment systems before they cause issues for operations.

CHOOSE YOUR PATH

BROWNFIELD REPLACEMENT(MODULAR SYSTEMS)

Fast, fit-for-access retrofits that tie into legacy utilities and restore uptime quickly.

GREENFIELD NEW BUILDS(SKIDDED & ENGINEERED)

Single-skid packages built to spec for shipyard lift-and-set installation and clean EPC review.

Applicable Product Families

BLUECUBE RO WATERMAKERS (MODULAR)

LEARN MORE.png?width=396&height=388&name=rp_pressureset_250x250%20(2).png)

PRESSURE SETS (MODULAR)

LEARN MORE

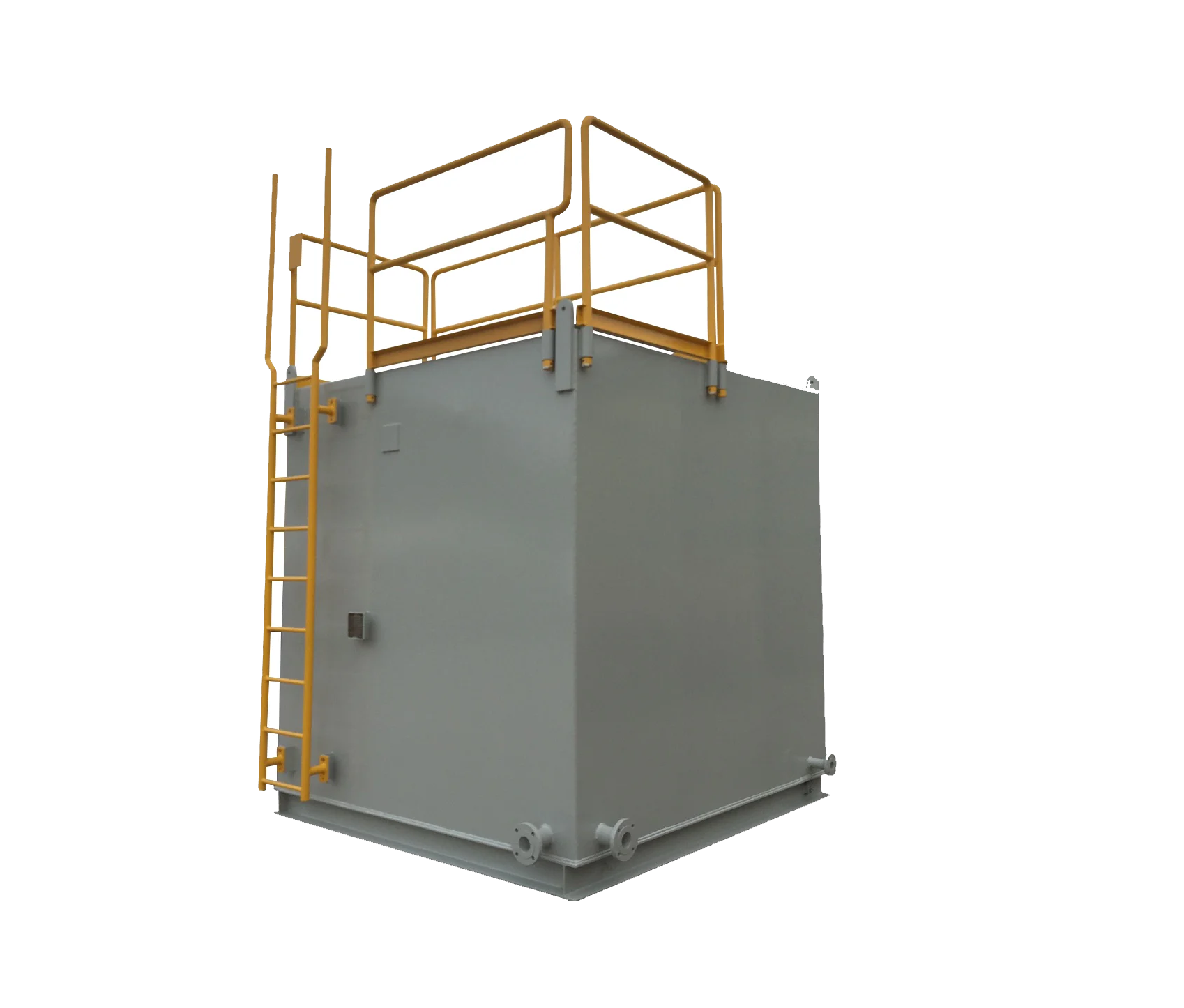

POTABLE WATER STORAGE TANKS (REPLACEMENTS)

LEARN MORE.png?width=825&height=718&name=C_Painted_Front_Left__26216.1532008898.1280.1280__96650%20(2).png)

CRAPZAPPER MSD (COMPACT)

LEARN MORE

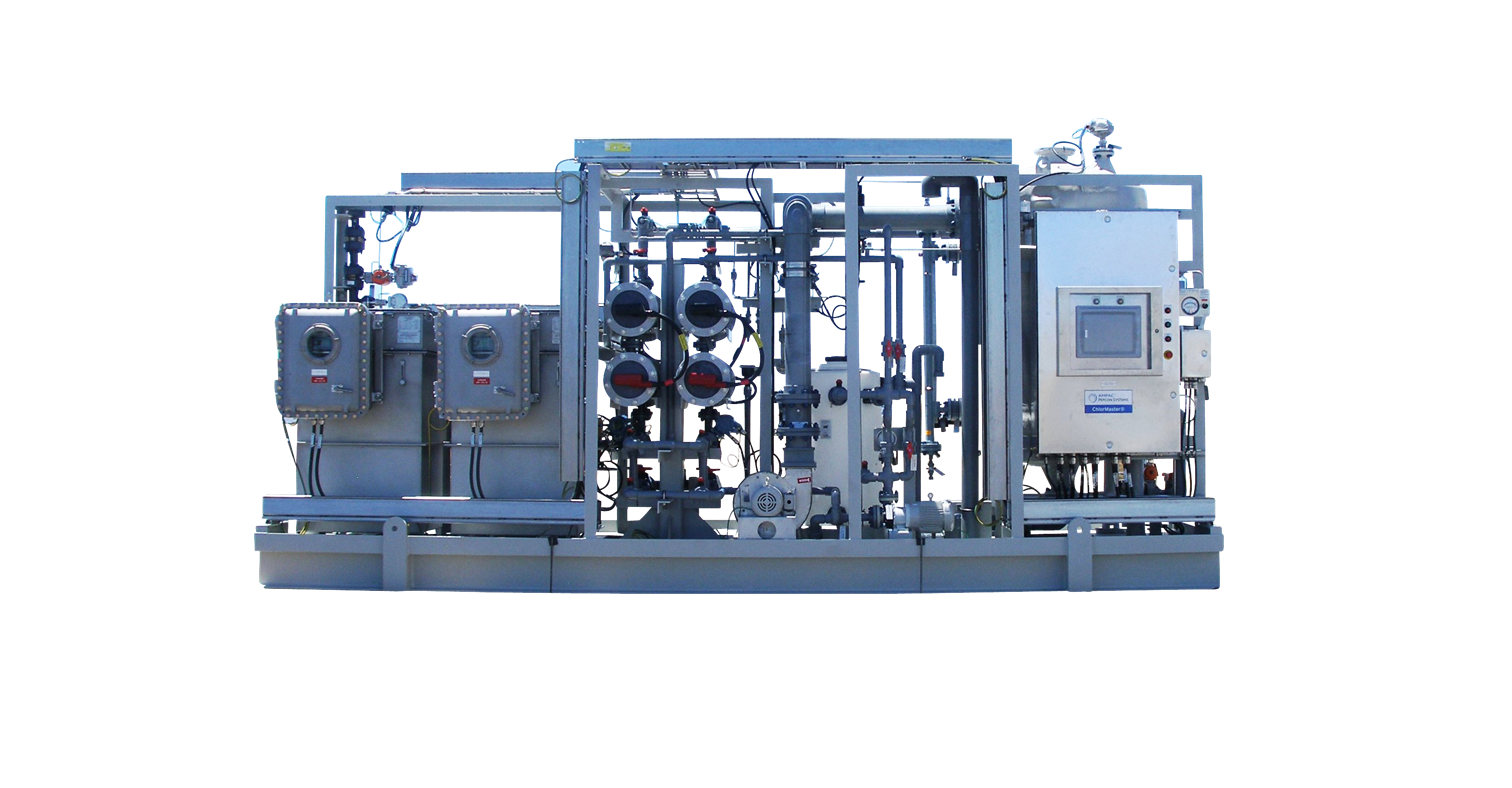

PEPCON FLEXIFIT EC (MODULAR)

LEARN MOREWhat We Deliver:

- Modular replacements sized to pass through restricted access routes and tie directly to existing utilities—with no major structural changes.

- Hazardous-location–ready equipment and offshore-duty construction for safety and compliance.

- Rapid change-out plans that minimize outage and get crews back to steady state.

How Projects Run

What Success Looks Like

A system that fits through access constraints, mounts in the same footprint, and matches existing tie points—delivering first-time start-up, reliable operation, and minimal downtime.

.png?width=1200&height=1200&name=Untitled%20design%20(18).png)

Frequently Asked Questions

How fast can a replacement system be installed and brought online?

Our brownfield modules are designed around your existing tie-ins and access routes, so installation is measured in hours or days—not weeks. Systems are fully function-tested before shipment to minimize offshore hookup time and speed commissioning.

Can your systems fit through our hatches and stairwells?

Yes. All modules are dimensioned for offshore access limits. We break down systems into subassemblies sized to pass through hatches, ladders, and stairwells, then reassemble offshore for a clean tie-in.

Will the new system match our existing piping and electrical tie-points?

Replacements are engineered to your legacy connection dimensions. Tie-in points are confirmed during the assessment phase so you don’t face field modifications or unplanned hot work offshore.

Are your packages certified for hazardous locations?

Yes. Our systems can be supplied for either safe-area duty or with full hazardous-area certification. Where HazLoc is required, we offer IECEx and CSA/UL certification levels, with documentation provided in full.

What documentation do you provide for approvals?

Each package comes with a standard documentation set covering installation, operation, and maintenance. Additional documents can be added based on client requirements identified during the needs assessment.

How do you minimize downtime during change-out?

We plan the swap around your outage window. Pre-assembled modules, confirmed tie-in points, and proven change-out procedures reduce hookup and testing time so crews return to steady state fast.

How do you handle spares and long-term support?

Every system ships with a recommended spares list, and we use industry-standard components wherever possible to avoid obsolescence. Our offshore-trained service team is available for commissioning, training, and long-term support.

What if our old system failed unexpectedly—can you respond quickly?

Yes. We maintain rapid-response engineering and modular designs that shorten lead times. Emergency consults can begin immediately to confirm fit, scope, and options for a fast replacement path.