.png?width=907&height=474&name=H2O_0001cv2%20(2).png)

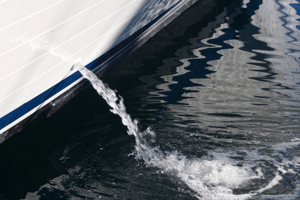

Oily Water Separators Are Key to Keeping Oceans and Waterways Free From Oily Waste

Oily wastes are byproducts of all operating ocean-going vessels. Around the globe, these vessels generate millions of tons of oily waste annually. According to the United States Environmental Protection Agency, oily bilgewater is the mixture of water, oily fluids, lubricants, grease, cleaning fluids, and other wastes that accumulate in the lowest part of a vessel from a variety of sources, including engines (and other parts of the propulsion system), piping, and other mechanical and operational sources found throughout the machinery spaces of a vessel.

See what size OWS system is right for your vessel with our BOSS by H2O Sizing Calculator

According to the EPA, separator technologies have advanced in recent years, improving the effectiveness of oily bilgewater treatment. Current regulations of oily bilgewater discharge from vessels are based on Annex I of the International Convention for the Prevention of Pollution From Ships, developed in 1973 and modified in 1978 (MARPOL 73/78). Under MARPOL, all ships over 400 gross tons (GT) must have equipment installed onboard that limits the discharge of oil into the oceans when a ship is en route.

An oily water separator (OWS) is a piece of equipment used to separate oil and water mixtures into their separate components. On marine vessels, OWS systems separate oily waste from bilge water before being discharged into the environment. With current maritime regulations stating that the oil content of your discharged water must be less than 15 ppm, your OWS can help you achieve that goal, but only if it's up to the task and adequately sized for your system and your needs.

An oily water separator (OWS) is a piece of equipment used to separate oil and water mixtures into their separate components. On marine vessels, OWS systems separate oily waste from bilge water before being discharged into the environment. With current maritime regulations stating that the oil content of your discharged water must be less than 15 ppm, your OWS can help you achieve that goal, but only if it's up to the task and adequately sized for your system and your needs.

Make Sure You Size Your OWS Correctly

The proper sizing of the OWS on any vessel is critical to its performance.

- If sized too small, the OWS system will work continuously but won't be able to keep up with the production of bilge water. As a result, you may face a possible shutdown of operations or costly storage and shipping of bilge water to shore.

- If sized too large, the OWS will keep up with bilge water production; however, the additional cost and footprint make a large OWS less cost-effective than an appropriately sized model.

Sizing Your OWS Strategically

How do you know what size your oily water separator should be? Here are the key factors you'll need to take into account.

The Size of Your Vessel

The Size of Your Vessel

Sizing your separator may be as simple as following the standard for your vessel's size. However, OWS sizing standards range from 400 to over 15,000 gross tons, and while the BOSS by H2O Sizing Calculator will give you an idea of the right OWS system and components for your vessel, contacting an expert for further assessment is still a good idea.

Engineering Specifications

An engineering team designs most vessels. Your vessel's specifications should match your oily water separator's required standard flow rate. You can easily select this range from our various BOSS OWS sizes.

The Available Space on Your Vessel

Space is essential on any vessel, and your boat may have limited space for your OWS. If you have a smaller vessel, consider selecting one of the more efficiently sized BOSS systems like the Mini-BOSS.

The Type of Contamination in the Bilge

Consider the bilge that needs treating in your area. Is it primarily floating-free oil? Or is it emulsified, mixed with the water without separation? Your answer will influence how much oil-absorbing media you will consume. Each BOSS OWS has a specific amount of media. You may consume more media in an area with highly emulsified oils. This information is vital to know before selecting your OWS.

The Proposed Run Time of Your System

Finally, consider this question: How long will you be using your OWS at each given time? Our various separators are designed for different frequencies of use. For example, the BOSS OWS is designed for continuous, 24/7 service. The Mini-BOSS OWS is designed for shorter run times and lower volumes.

H2O LLC Is Here to Help You Size Your Separator

H2O LLC Is Here to Help You Size Your Separator

Sizing your OWS is vital to the functionality of your system and your ability to avoid steep fines. Fortunately, at H2O, we can provide a range of systems ideally suited for various vessels of varying sizes.

Our expert technicians are happy to help you assess your needs and recommend the perfect OWS.

Check out our BOSS by H2O Sizing Calculator, and then call our friendly team today for a timely response and the information you need to select the perfect OWS system or components for your vessel.

Specifications of the Various OWS Systems You Could Select

These are the BOSS separators offered by H2O.

- BOSS 25T-107 & BOSS 45T-107

- Designed for rig, FPSO, and production platform applications, these systems can be equipped for hazardous areas and harsh weather applications. With flow rates from 25-45 gpm (5.6-10.2m3hr) these systems comply with USCG, ABS, BV, and MED approvals per IMO MEPC 107(49).

- BOSS 2.2T-107YO

- Features color options, easy-to-change dual cartridges, or a longer-lasting bulk media tank.

- BOSS 2.2T-107 (cartridges)

- These cartridges feature an adjustable flow rate for optimal efficiency, ease of change, and a longer-lasting bulk media tank.

- Complies with USCG, ABS, BV, and MED approvals per IMO MEPC 107(49).

- BOSS 5T-107 (cartridges)

- Designed for vessels 1,600-4,000 GT, these cartridges feature an adjustable flow rate for optimal efficiency, ease of change, and a longer-lasting bulk media tank.

- Complies with USCG, ABS, BV, and MED approvals per IMO MEPC 107(49).

- BOSS 11T-107 (cartridges)

- These cartridges have been designed for vessels greater than 4,000GT with the ability to serve as a longer-lasting bulk media tank.

- IMO certified with an adjustable flow control valve to always obtain the targeted flow rate.

- Mini-BOSS

- This oily water separator meets IMO-certified standards even though small vessels are not subject to IMO regulations.

- These units have a certified flow of up to 2 GPM.

- With its small footprint and easy installation, the MiniBOSS makes for an effective and economical choice of oil water separators.

Contact our friendly team today to select your vessel's perfect OWS system or components.