STRUGGLING TO CLEAR DOCUMENTATION REVIEWS—AND KEEP SYSTEMS RUNNING NONSTOP OFFSHORE?

From tight-access retrofits that match existing tie points to Spec-compliant, single-lift packages, we deliver reliable freshwater, disinfection, storage, and sanitation systems that install quickly and run 24/7 offshore for decades.

WHO WE SERVE

OIMs, Maintenance Supervisors, Facilities Engineers, Operators/Technicians, Onshore Maintenance Coordinators; EPC Lead/Package Engineers and Procurement for new builds. These teams rely on providers who can meet specifications without review cycles dragging on, deliver systems when promised, and support them reliably over the long term.

WHAT’S AT STAKE

(AND HOW WE HELP YOU SOLVE IT)

Existing Installations

(retrofits and replacements):

Replace failing equipment within severe space and access constraints; tie into legacy connection points; meet HazLoc and offshore exposure requirements—without stretching downtime windows. We design modular, right-sized replacements that fit through hatches, tie in quickly, and start up fast.

New builds

(EPC/FPSO projects):

Deliver complete, spec-compliant, single-skid packages with rigorous documentation and certification cycles. Our RapidFlow Development Process enables concurrent engineering and modular pre-testing, streamlining review cycles and reducing schedule risk. Packages are engineered to spec for smooth approvals and on-time delivery, giving EPCs confidence in both technical compliance and schedule certainty.

-1.png?width=1200&height=1200&name=Untitled%20design%20(15)-1.png)

CHOOSE YOUR PATH

Existing Installs

Fast, fit-for-access retrofits that tie into legacy utilities and restore uptime quickly.

New Builds

Single-skid packages built to spec for shipyard lift-and-set installation and clean EPC review.

CORE PRODUCT FAMILIES FOR OFFSHORE

BLUECUBE RO WATERMAKERS

Capacity-matched freshwater packages for brownfield replacements or EPC specs.

RENTAL QUOTE.png?width=396&height=388&name=rp_pressureset_250x250%20(2).png)

PRESSURE SETS

Deliver Stable water pressure even at the top deck; modular for brownfield, skidded for greenfield.

RENTAL QUOTE

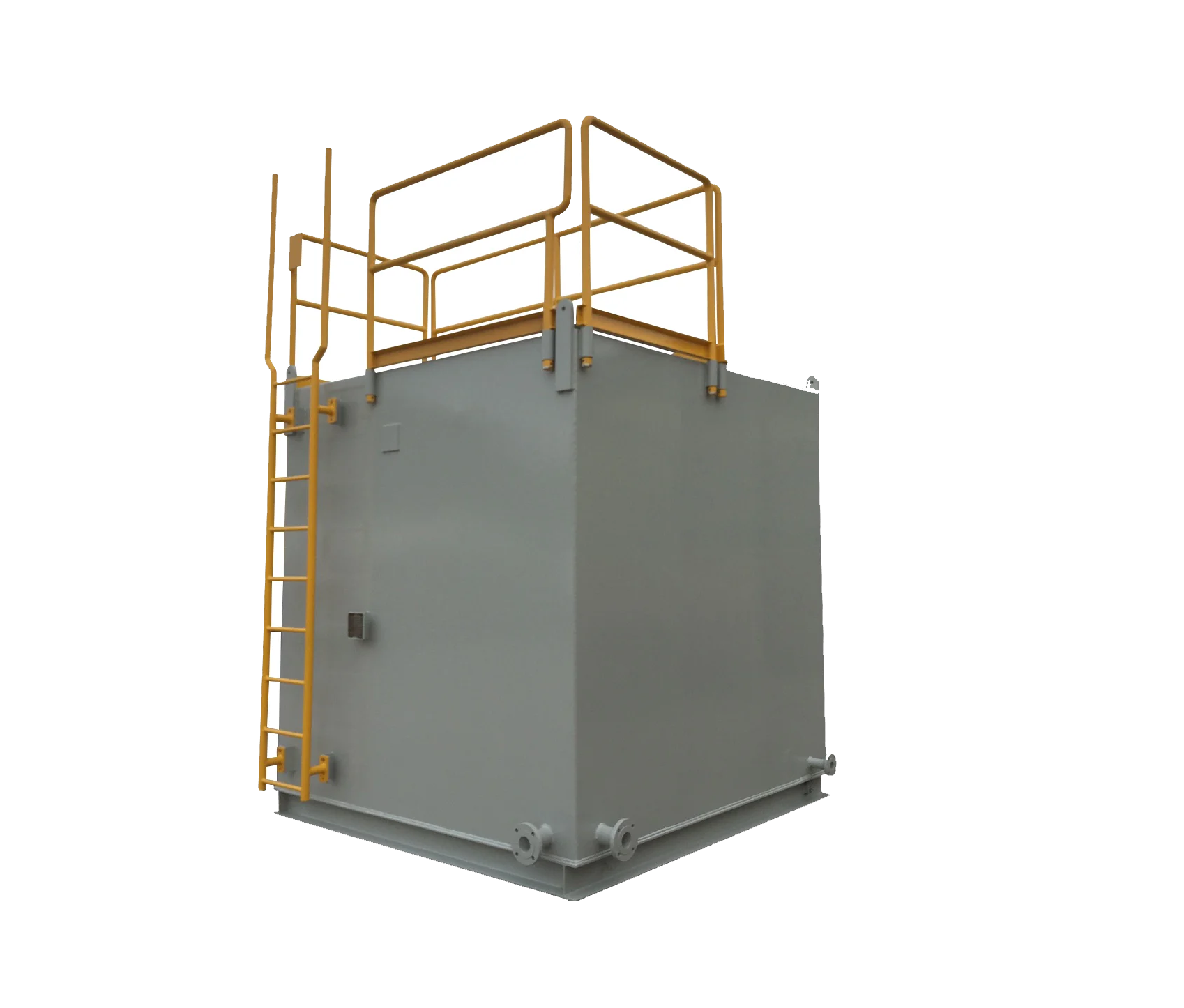

POTABLE WATER STORAGE (TANKS/SYSTEMS)

Materials and documentation aligned to potable standards and offshore duty.

RENTAL QUOTE.png?width=825&height=718&name=C_Painted_Front_Left__26216.1532008898.1280.1280__96650%20(2).png)

CRAPZAPPER SEWAGE TREATMENT SYSTEMS (MSDS)

Robust globally certified MSD solutions for offshore sanitation.

RENTAL QUOTE

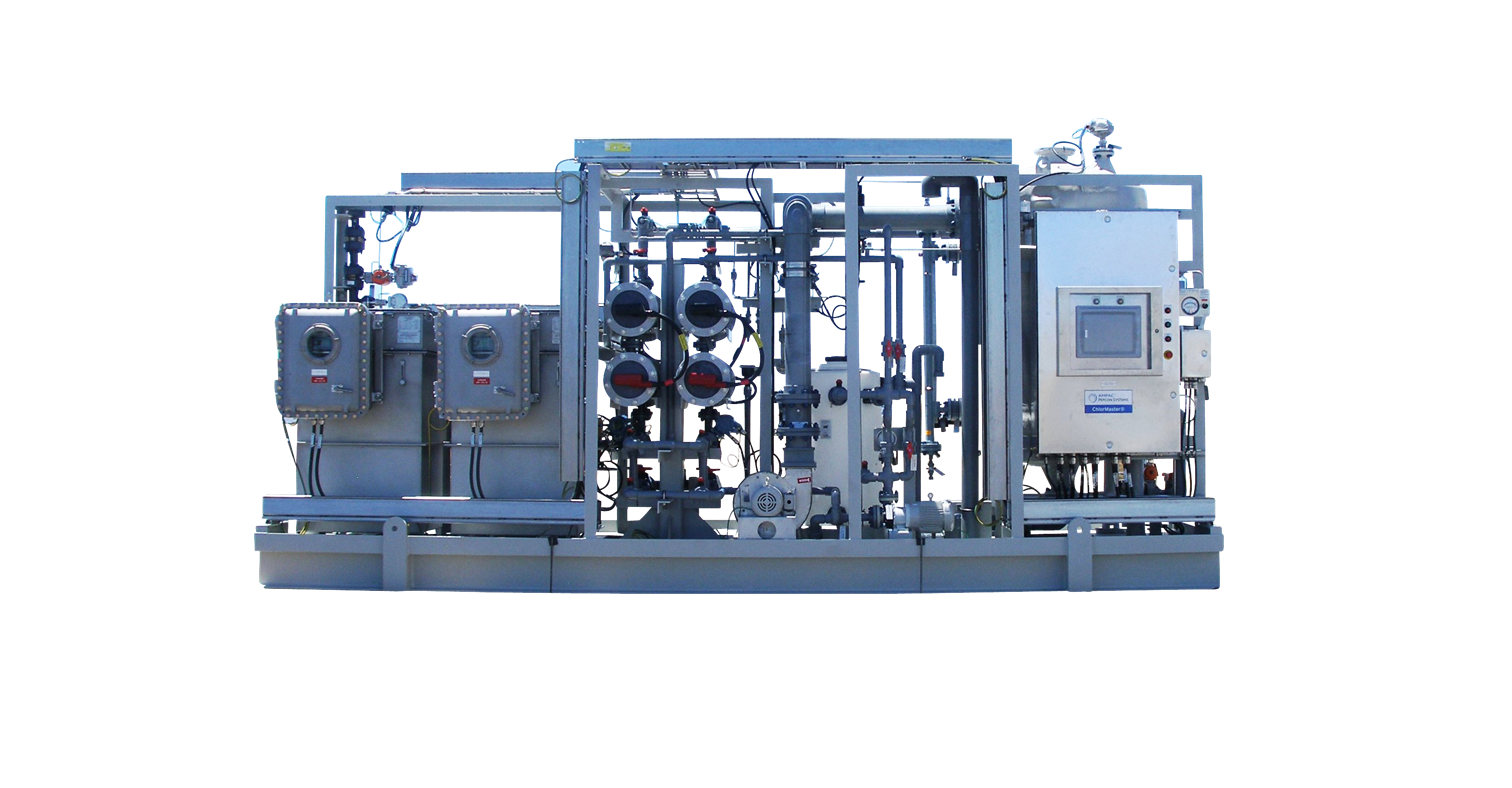

PEPCON ELECTROCHLORINATION (BIOFOULING CONTROL)

Continuous hypochlorite dosing to prevent marine growth and protect seawater circuits..

RENTAL QUOTEWHY H2O OFFSHORE?

Certified for hazardous locations, engineered for harsh offshore conditions, and built with the highest-quality components and materials—supported by documentation packages aligned to EPC review cycles. Our systems clear approvals quickly, install cleanly, and keep projects on schedule.

FREQUENTLY ASKED QUESTION

Are your systems certified for hazardous locations (HazLoc/IECEx/ATEX)?

Yes. Our offshore systems are designed and certified to meet the hazardous-area classifications specified for your platform or FPSO, including IECEx and ATEX standards. Certification documentation is provided in full with each package

Can your equipment handle the offshore environment long-term?

Yes. All materials and coatings are selected for offshore duty, with proven corrosion resistance and environmental durability. Enclosures, structural components, and electrical gear are designed for continuous exposure to marine conditions

How do you ensure your systems meet our specifications and documentation requirements?

We build to your project specifications from the start, using only high-quality, spec-compliant components. Every system ships with a complete documentation package aligned to EPC and client review cycles (VDRL/SDRL, ITPs, FAT/SAT records, etc.) to keep approvals moving

How much space and access do your systems require during installation?

We design systems around your constraints. For new builds, packages are delivered as single-lift skids. For retrofits and replacements, we offer modular or hatchable designs that break down to fit through confined spaces and tie in cleanly to existing connections.

How quickly can your systems be installed and started up?

Installation is planned into the design. Tie-in points are aligned to your existing piping and electrical infrastructure, and systems are fully function-tested before shipment. This minimizes offshore hookup time and enables fast commissioning/startup.

What level of support and training do you provide after delivery?

We provide full commissioning, operator training, and long-term support. Our offshore-experienced technicians handle start-up, and we remain available for remote and onsite troubleshooting, maintenance, and parts support throughout the life of the system.

How do you handle spare parts and long-term maintainability?

We select widely available, industry-standard components whenever possible to avoid obsolescence and supply-chain delays. Each system ships with a recommended spares list, and our team can assist with stocking strategies and lifecycle planning.