Single-Skid Utility Packages Engineered for EPC Success

Spec-compliant, vendor-list components, and complete document packs for smooth reviews and on-time yard installs.

Who is this for?

Lead/Package Engineers and Procurement Specialists responsible for clearing rigorous reviews, meeting client specification requirements, and protecting shipyard schedules on new platforms and FPSOs.

THE GREENFIELD MANDATE

Deliver complete skids that lift and land cleanly, align with the spec, and move through rigorous documentation and certification cycles without churn.

.png?width=1200&height=1200&name=Untitled%20design%20(19).png)

CHOOSE YOUR PATH

BROWNFIELD REPLACEMENT(MODULAR SYSTEMS)

Fast, fit-for-access retrofits that tie into legacy utilities and restore uptime quickly.

GREENFIELD NEW BUILDS(SKIDDED & ENGINEERED)

Single-skid packages built to spec for shipyard lift-and-set installation and clean EPC review.

Applicable Product Families

BLUECUBE RO WATERMAKERS (SKIDDED)

LEARN MORE.png?width=396&height=388&name=rp_pressureset_250x250%20(2).png)

PRESSURE SETS (SKIDDED)

LEARN MORE

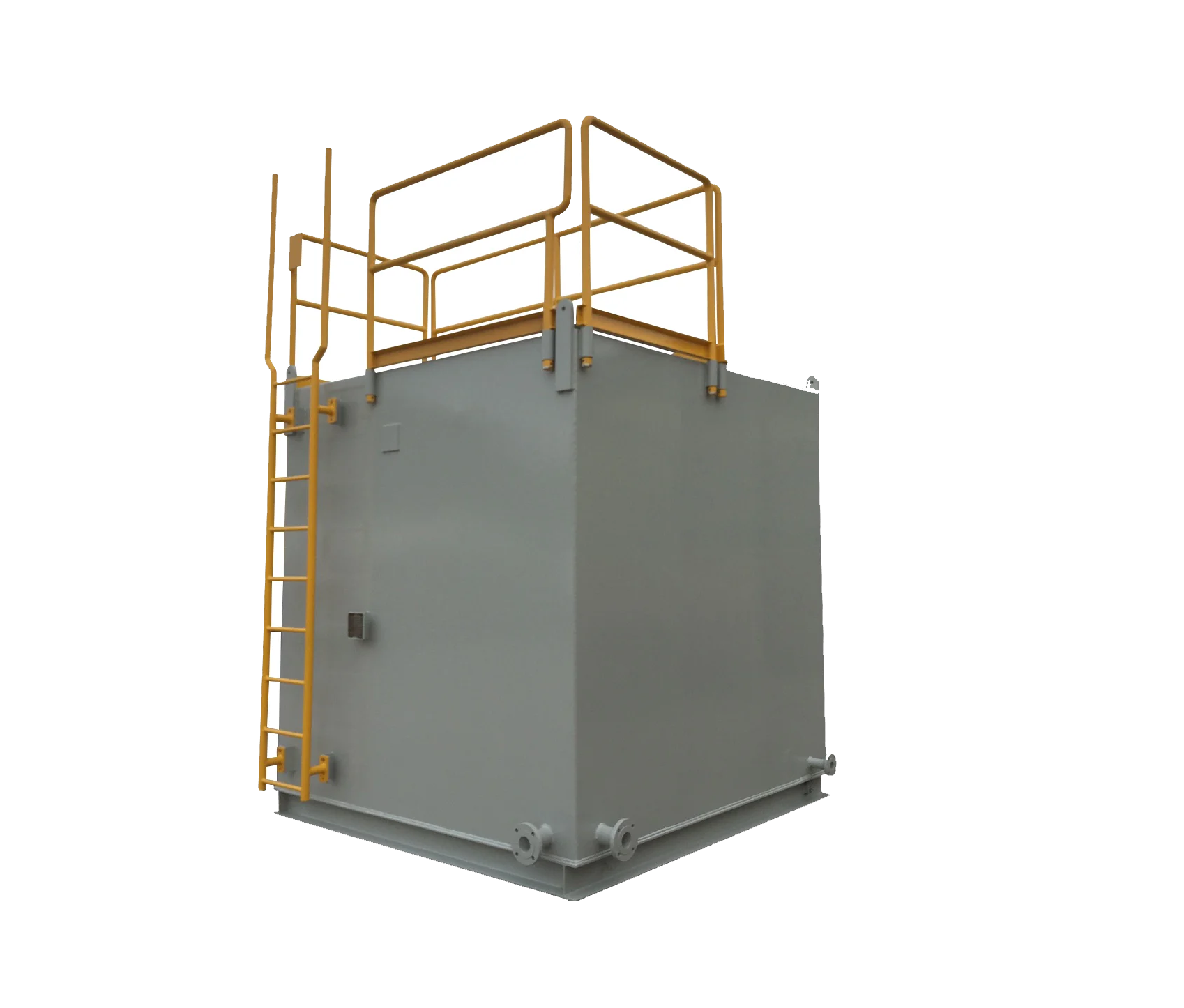

POTABLE WATER STORAGE TANKS

LEARN MORE.png?width=825&height=718&name=C_Painted_Front_Left__26216.1532008898.1280.1280__96650%20(2).png)

CRAPZAPPER SEWAGE TREATMENT

LEARN MORE

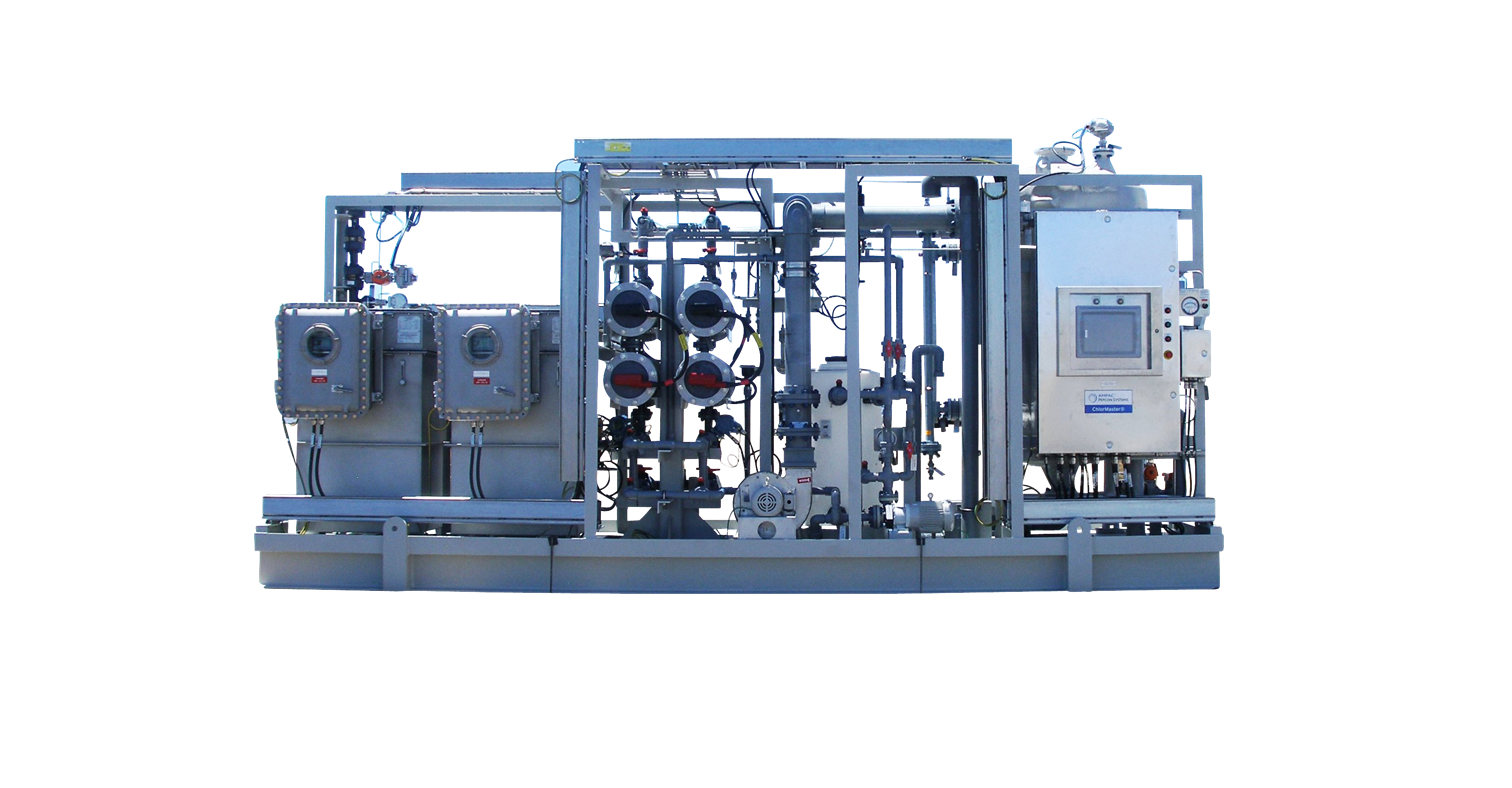

PEPCON FLEXIFIT EC (SKIDDED)

LEARN MOREWhat we deliver:

-

Single-skid systems engineered for shipyard lift-and-set with utilities and tie-ins placed per 3D model review.

- Full client-spec alignment across AVL components, coatings, materials, class/flag, and hazardous-area requirements.

- Gate-ready document sets (GA, P&ID, loads, I/O, test protocols) prepared to clear reviews without churn.

How Projects Run

Why it Works

Spec alignment, vendor transparency, and complete documentation—delivered through our Rapid Flow process—so technical reviews clear quickly, surprises are avoided, and yard schedules stay on track

Frequently Asked Questions

Can your systems fit through our hatches and stairwells?

Yes. All modules are dimensioned for offshore access limits. We break down systems into subassemblies sized to pass through hatches, ladders, and stairwells, then reassemble offshore for a clean tie-in.

Are your packages certified for hazardous locations?

Yes. Our systems can be supplied for either safe-area duty or with full hazardous-area certification. Where HazLoc is required, we offer IECEx and CSA/UL certification levels, with documentation provided in full.

What documentation do you provide for approvals?

Each package comes with a standard documentation set covering installation, operation, and maintenance. Additional documents can be added based on client requirements identified during the needs assessment.

How do you handle spares and long-term support?

Every system ships with a recommended spares list, and we use industry-standard components wherever possible to avoid obsolescence. Our offshore-trained service team is available for commissioning, training, and long-term support.